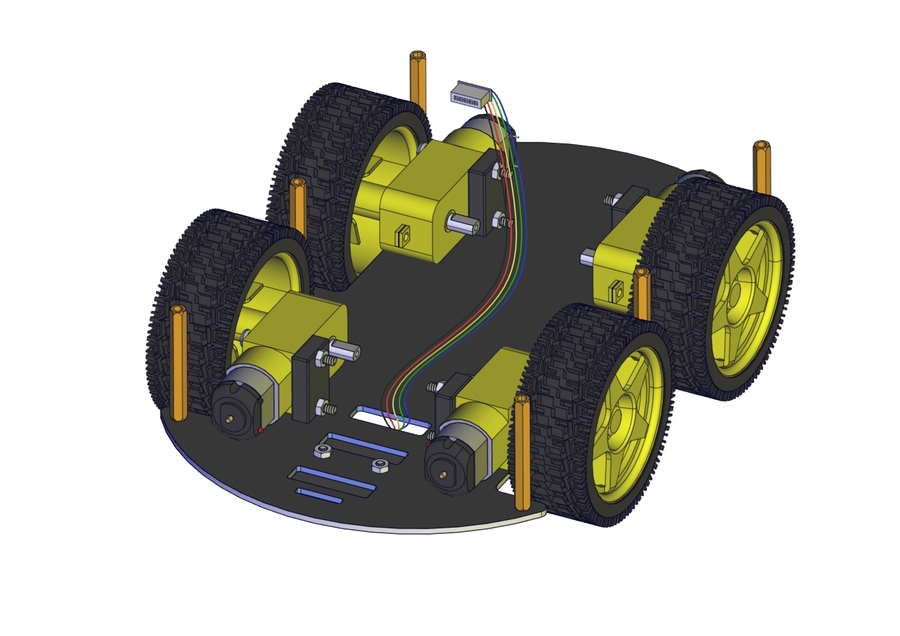

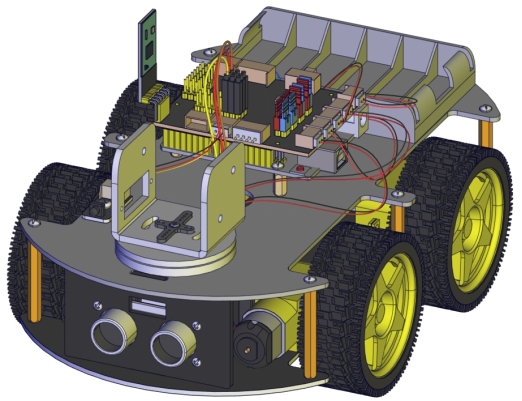

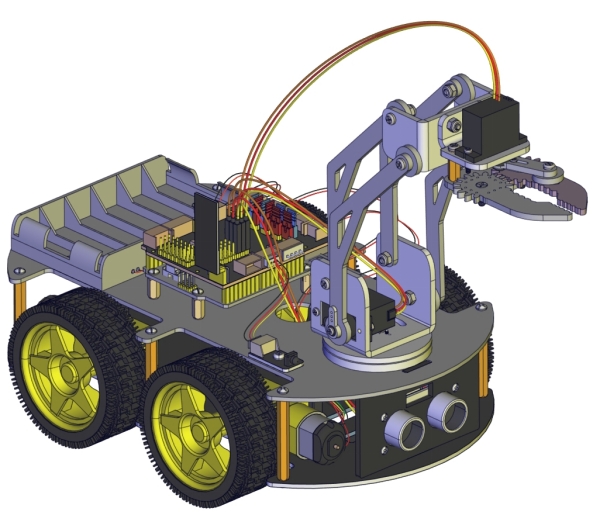

OpenELAB 4WD Mechanical Arm Robot Smart Car for Arduino

Product Link

Description

As science and technology develops by leaps and bounces, human society moves towards an era of intelligence and automation as well.

Our hands are weak and unresistant to ultra-cold and high temperature environment. In this regard, mechanical arms can totally supplant our hands and work for people.

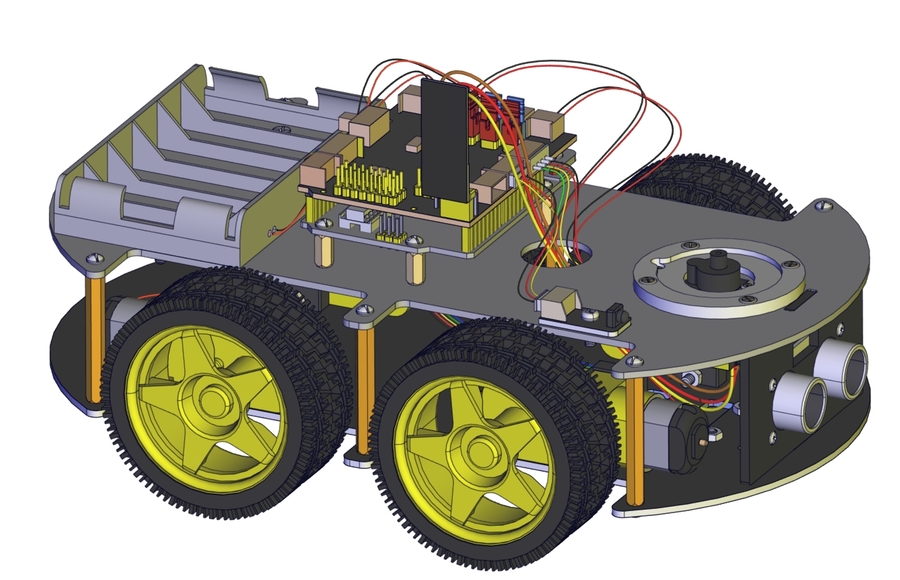

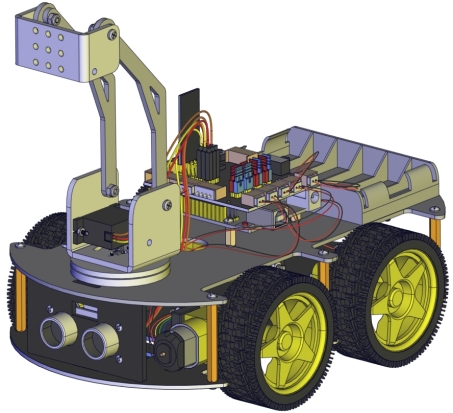

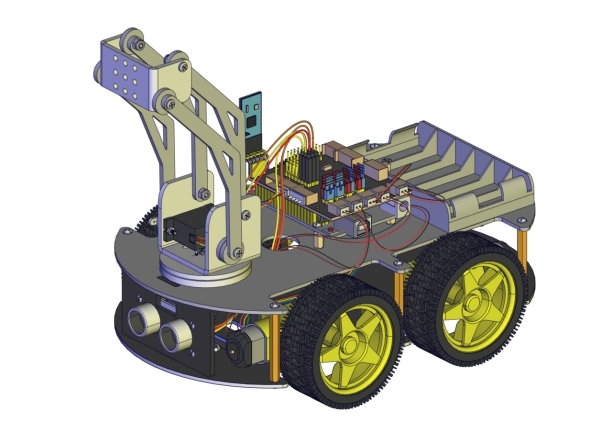

At present, KEYES group has designed this kind of smart mechanical arm car to tackle the shortcomings of most robot arms, clumsy and fixed. This mechanical smart car reacts and performs its functions by following commands sent by the cellphone connected.

Features

Multi-purpose Function: Anti-fall, obstacle avoidance, following, IR remote control, line tracking, automatically convey and so on.

Easy to Build: soldering circuit is not required.

High Tenacity: high performance car baseplate and metal mechanical arm

High Extension: expand other sensors and modules through motor driver shield.

Multiple Controls: IR remote control, fully automatic and App control(iOS and Android system)

Basic Programming:C language code learning.

Specification

Working voltage: 5v

Input voltage: 7-12V

Maximum output current: 3A

Maximum power dissipation: 25W (T=75℃)

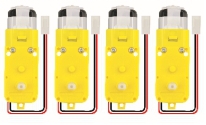

Motor speed: 5V 63 rpm / min

Motor drive form: TB6612 drive

Ultrasonic sensing angle: <15 degrees

Ultrasonic detection distance: 2cm-400cm

Bluetooth remote control distance: 20-50 meters (measured)

Bluetooth APP control: support Android and iOS system

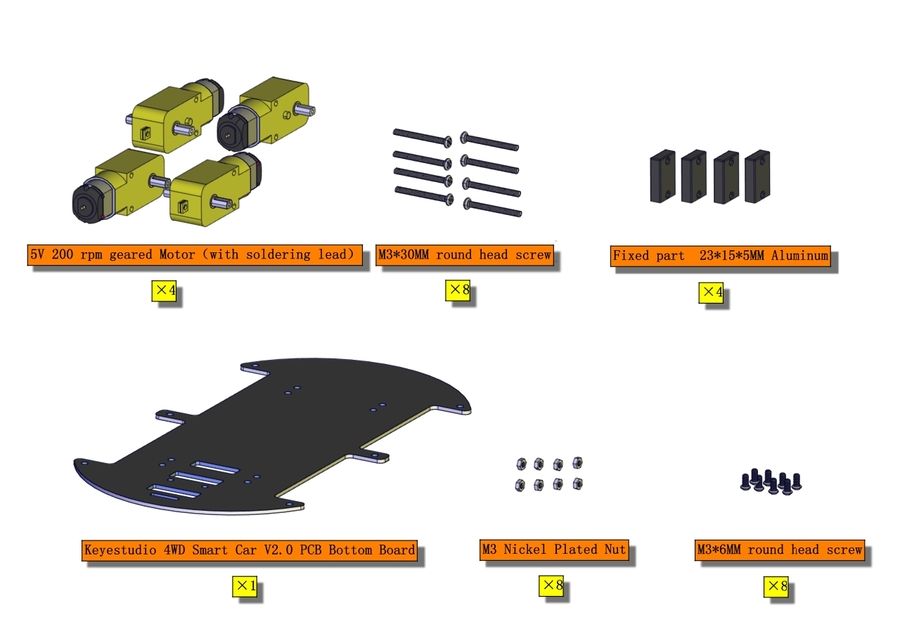

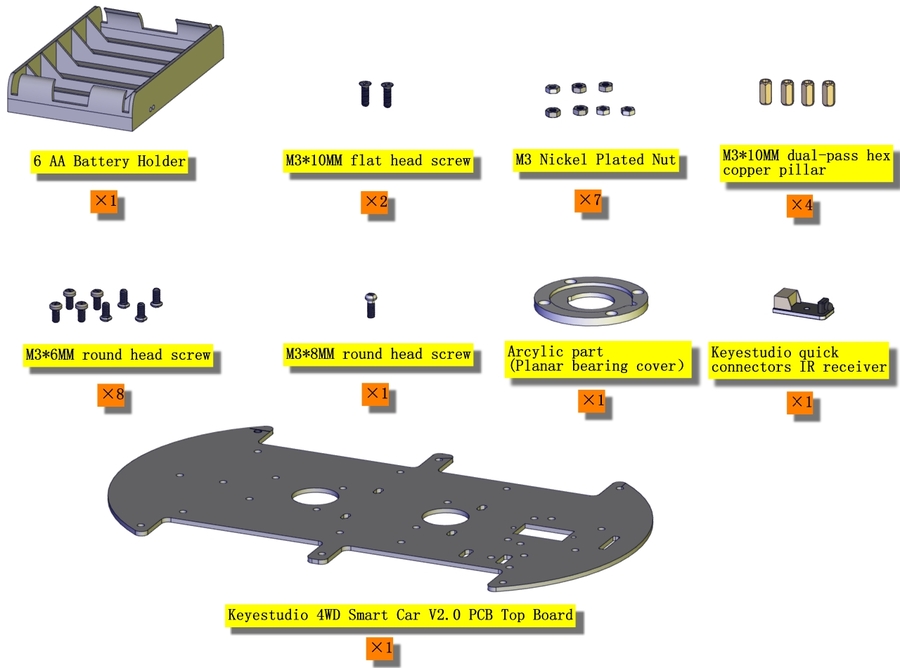

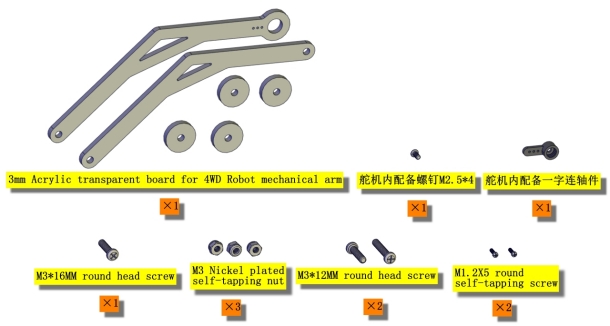

Kit list

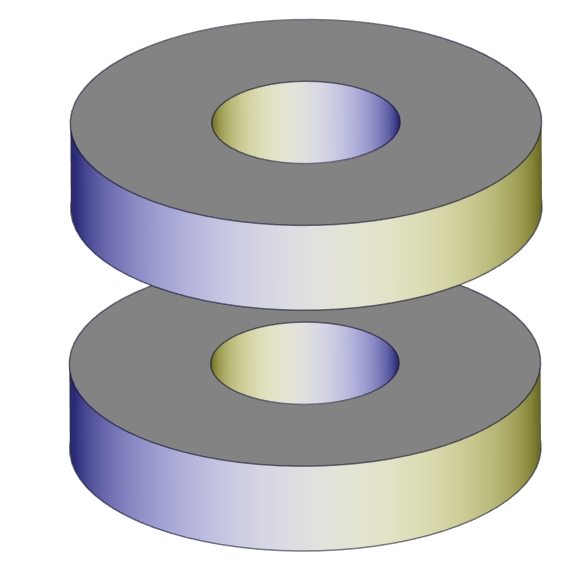

34

M2*10MM Round Head Screws

8

47

Black Ties 3*100MM

6

Getting Started with Arduino

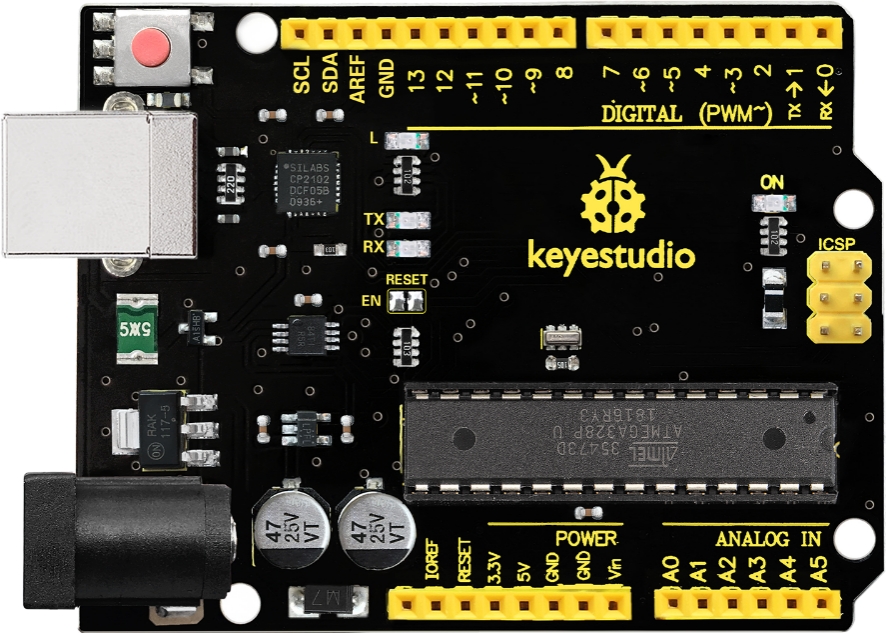

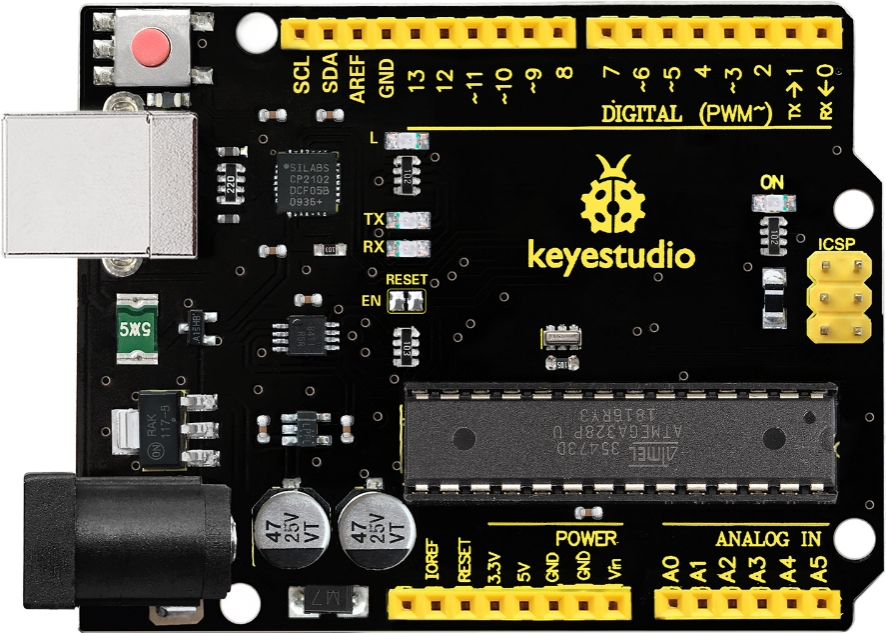

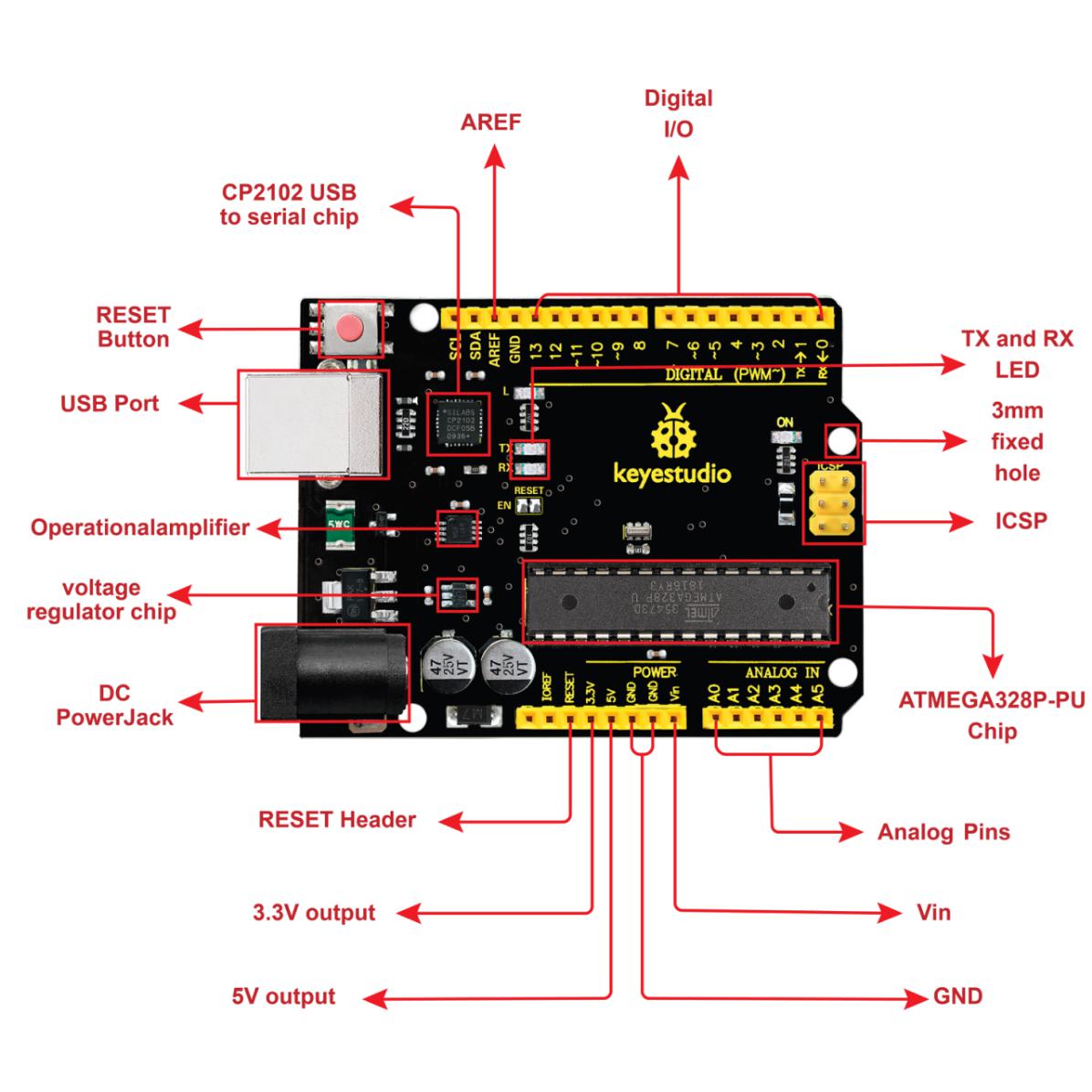

OpenELAB V4.0 Development Board

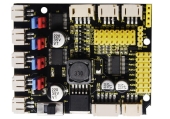

You need to know that OpenELAB V4.0 development board is the core of this smart car.

OpenELAB V4.0 development board is an Arduino uno -compatible board, which is based on ATmega328P MCU, and with a cp2102 Chip as a UART-to-USB converter.

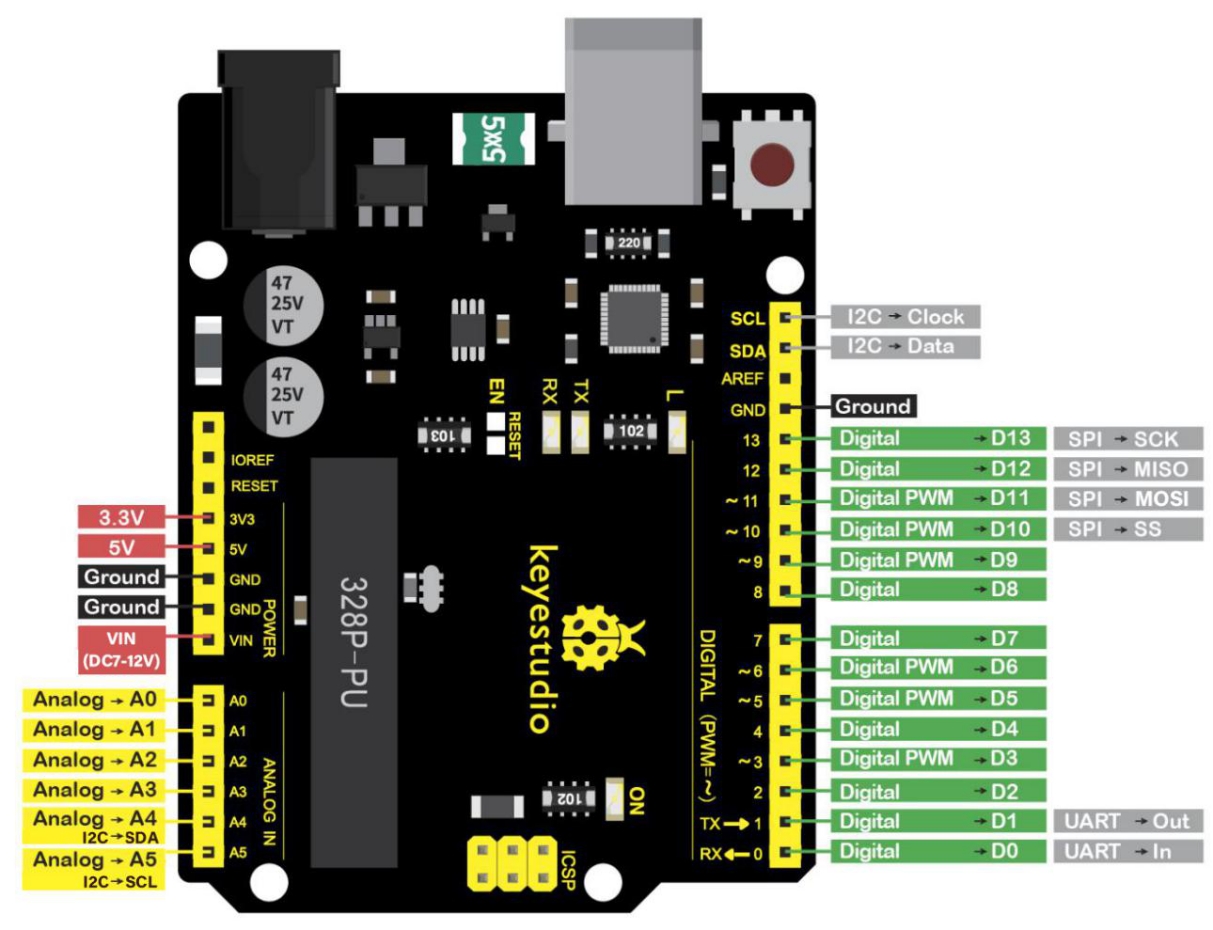

It has 14 digital input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a 16 MHz quartz crystal, a USB connection, a power jack, 2 ICSP headers and a reset button.

It contains everything needed to support the microcontroller. Simply connect it to a computer with a USB cable or power it via an external DC power jack (DC 7-12V) or via female headers Vin/ GND(DC 7-12V) to get started.

Operating Voltage

5V

Input Voltage (recommended)

DC7-12V

Digital I/O Pins

14 (D0-D13) (of which 6 provide PWM output)

PWM Digital I/O Pins

6 (D3, D5, D6, D9, D10, D11)

Analog Input Pins

6 (A0-A5)

DC Current per I/O Pin

20 mA

DC Current for 3.3V Pin

50 mA

Flash Memory

32 KB (ATmega328P-PU) of which 0.5 KB used by bootloader

SRAM

2 KB (ATmega328P-PU)

EEPROM

1 KB (ATmega328P-PU)

Clock Speed

16 MHz

LED_BUILTIN

D13

Installing Arduino IDE

Click the link to start learning how to download software, install drivers, upload code, and install library files.

https://getting-started-with-arduino.readthedocs.io

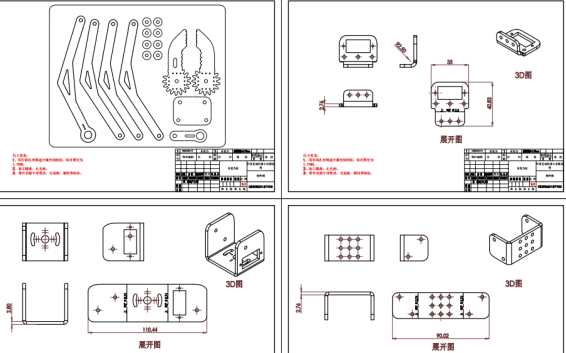

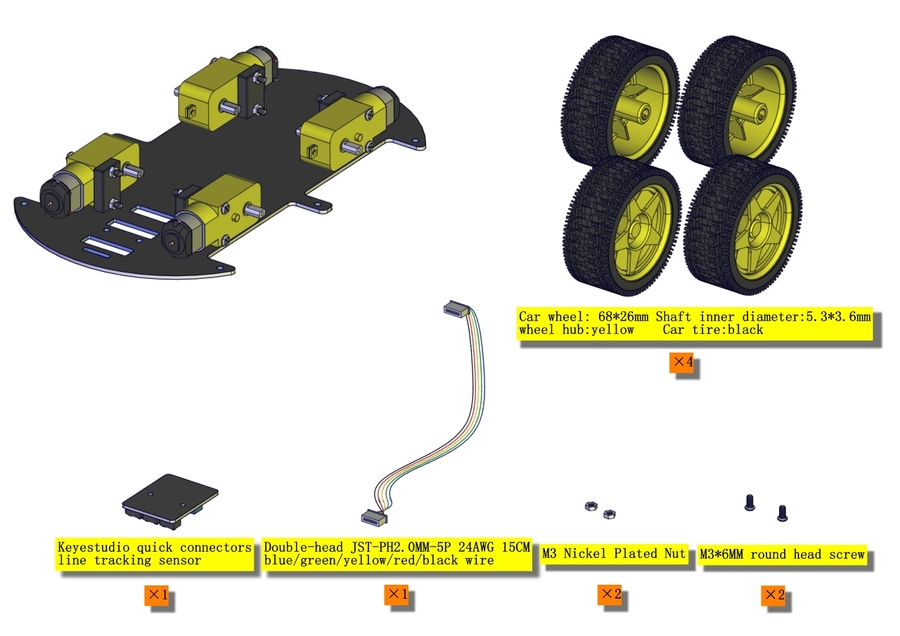

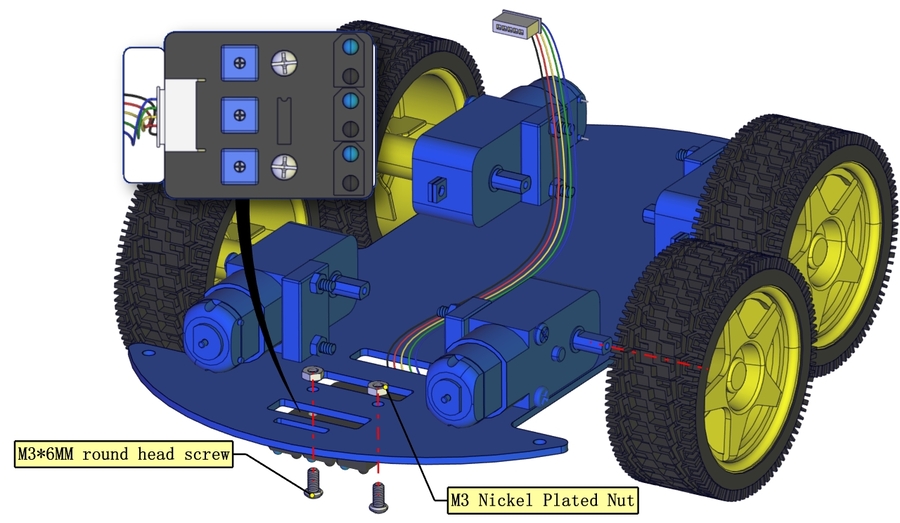

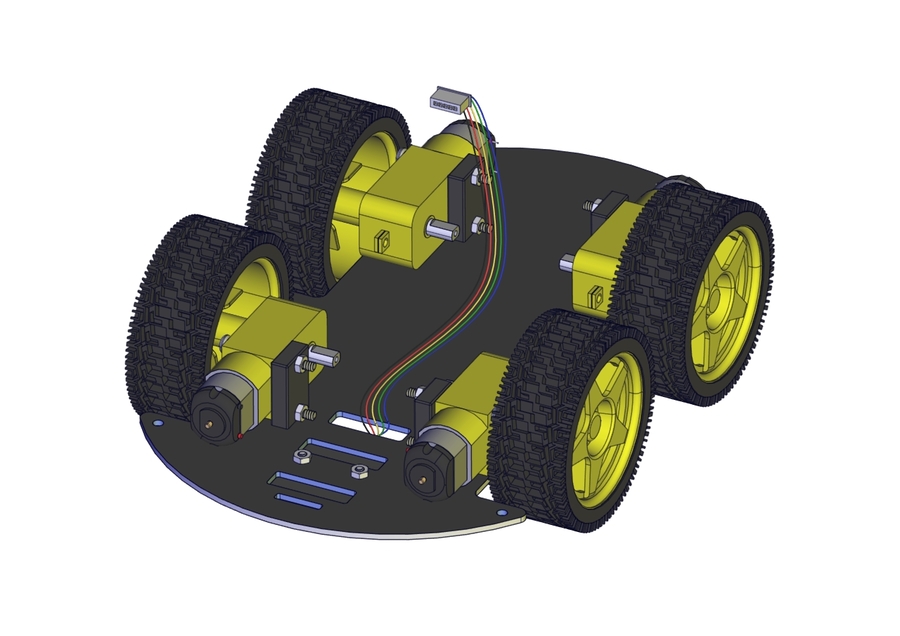

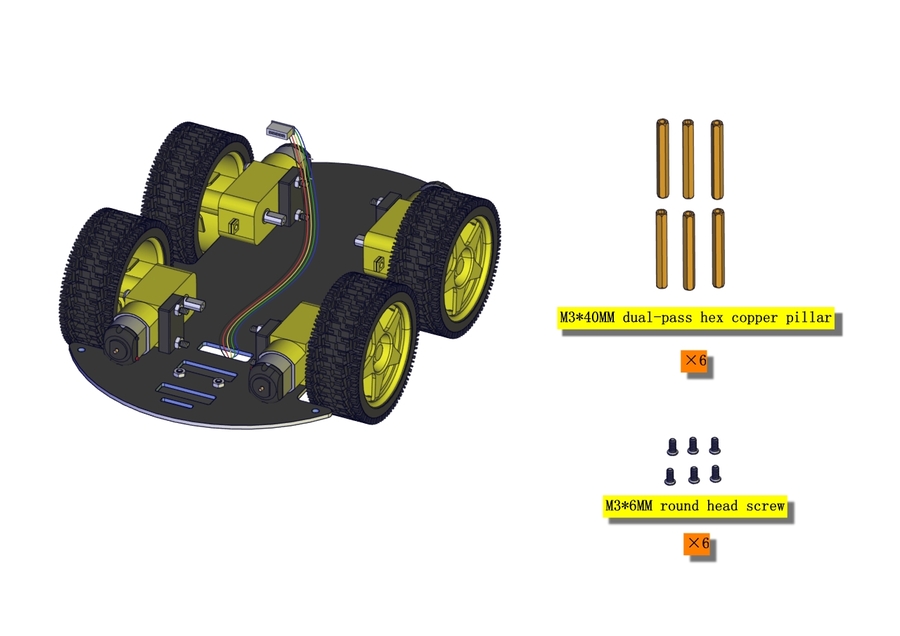

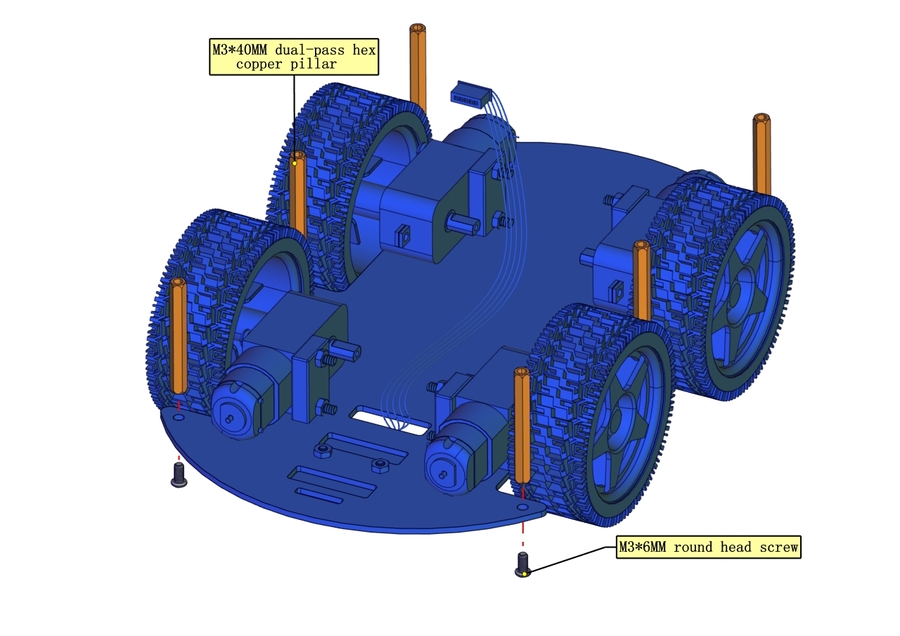

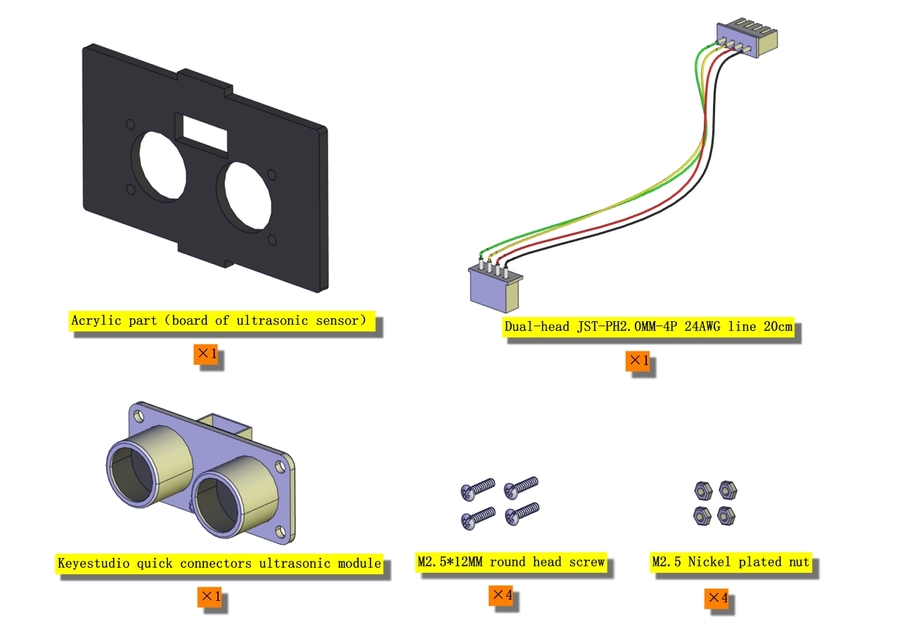

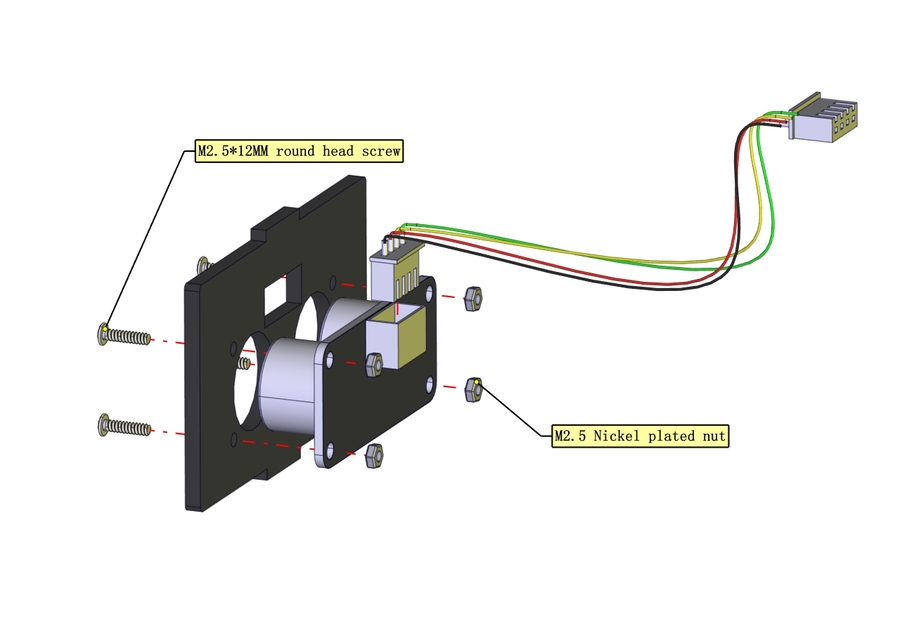

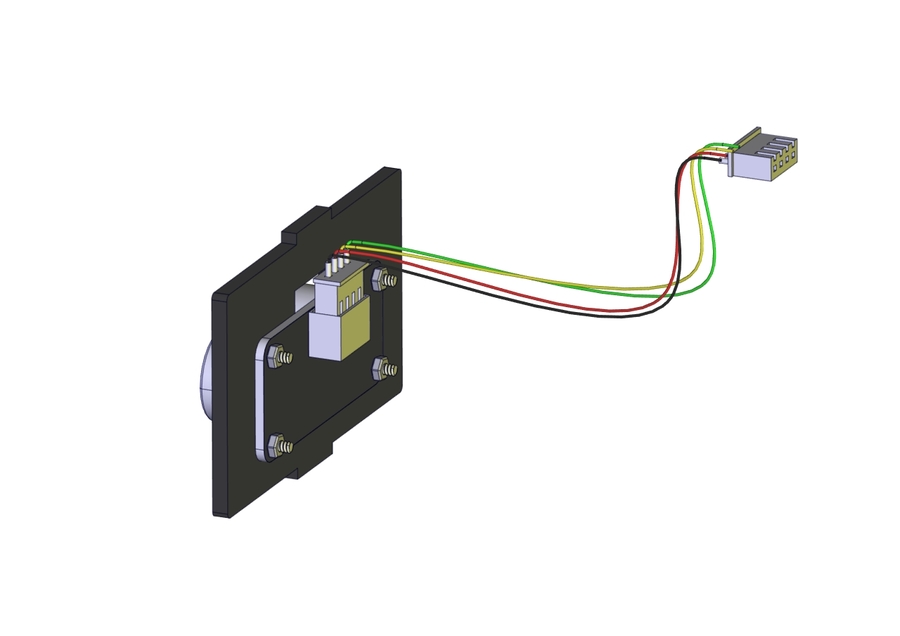

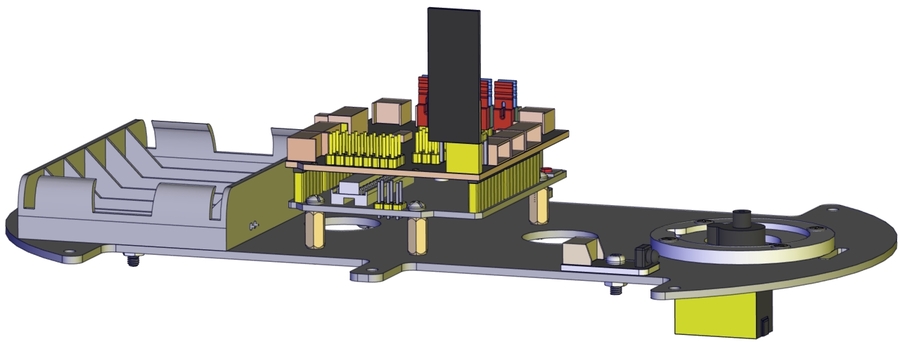

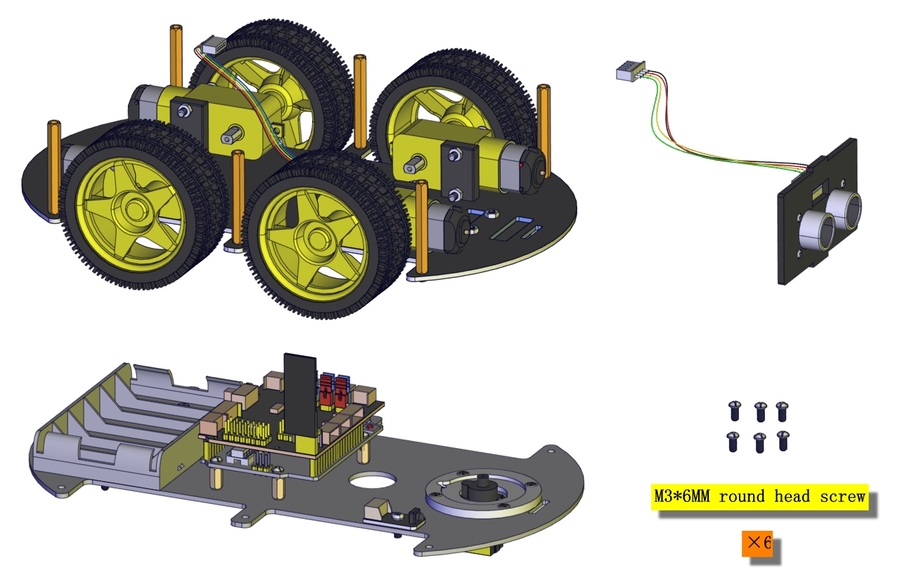

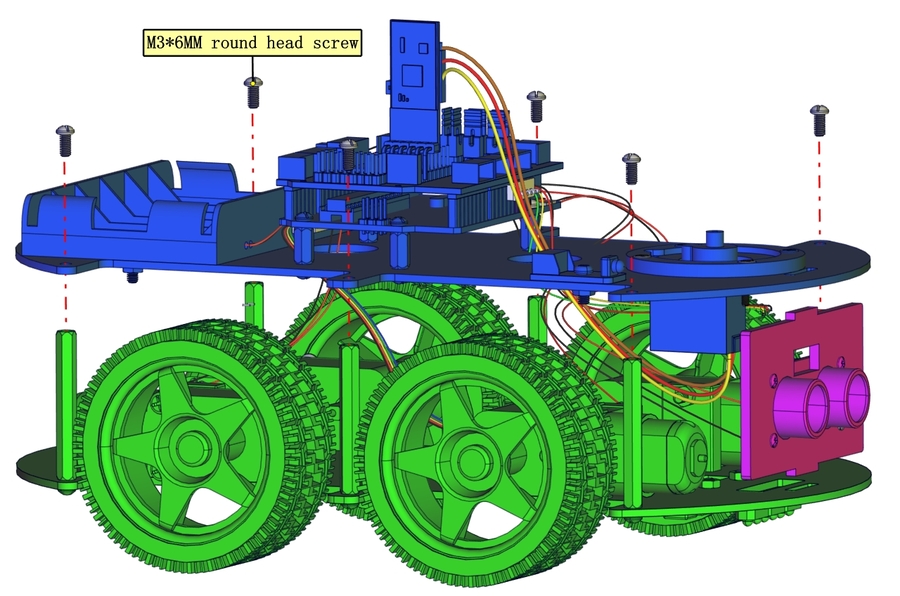

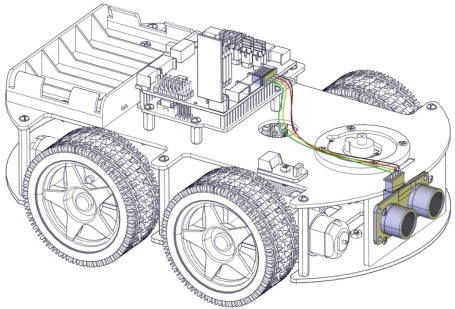

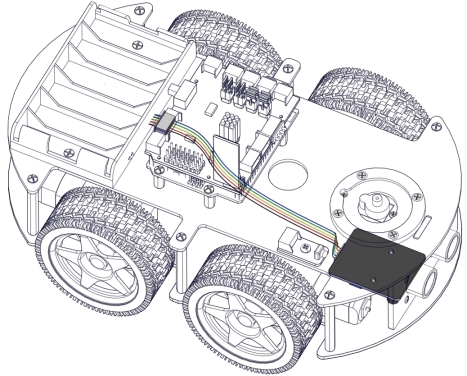

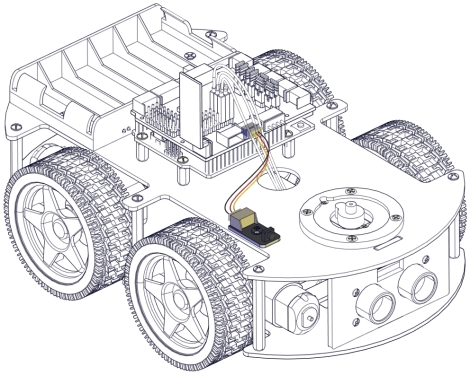

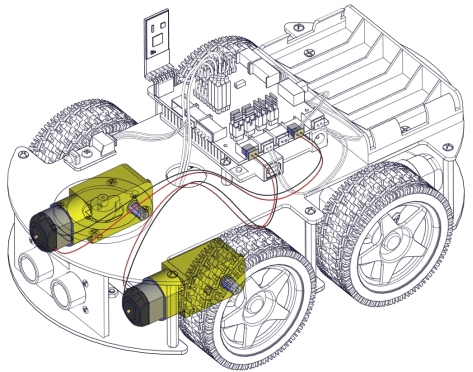

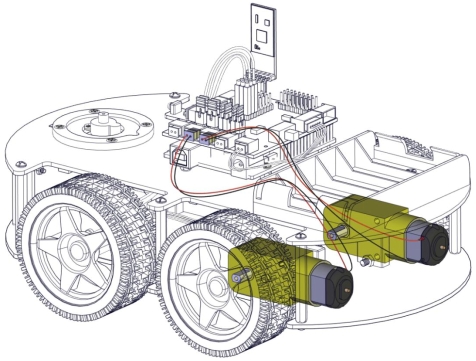

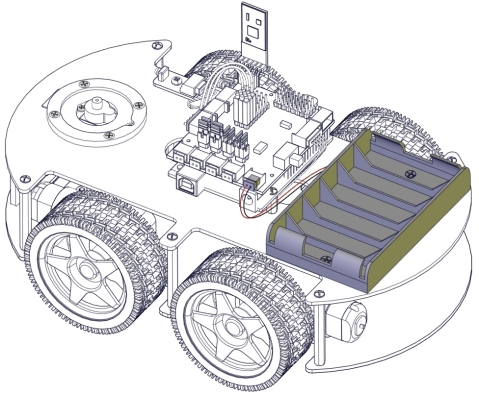

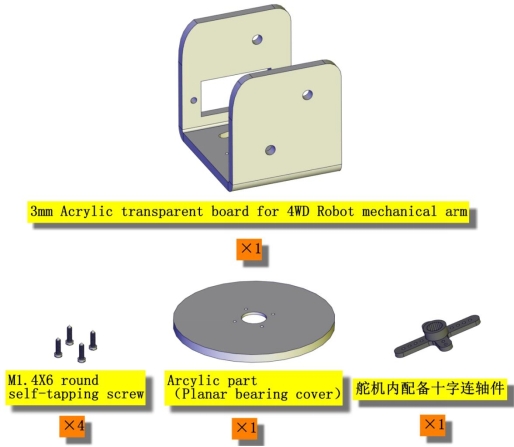

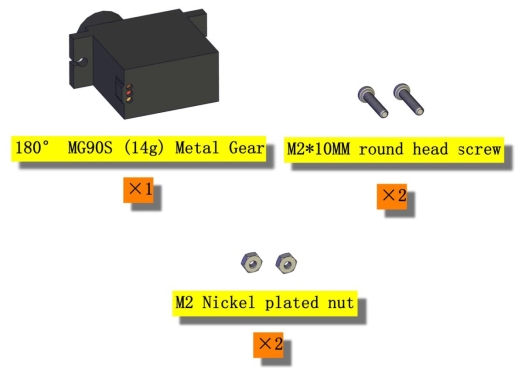

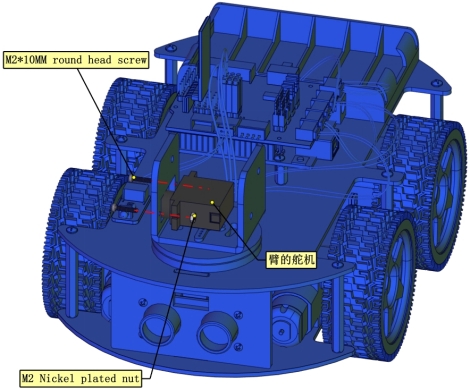

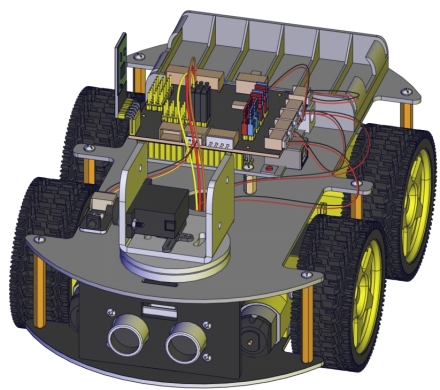

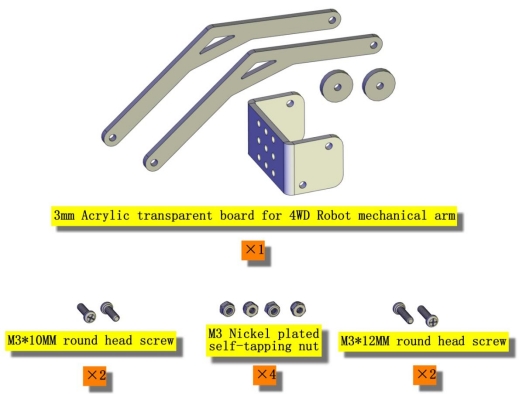

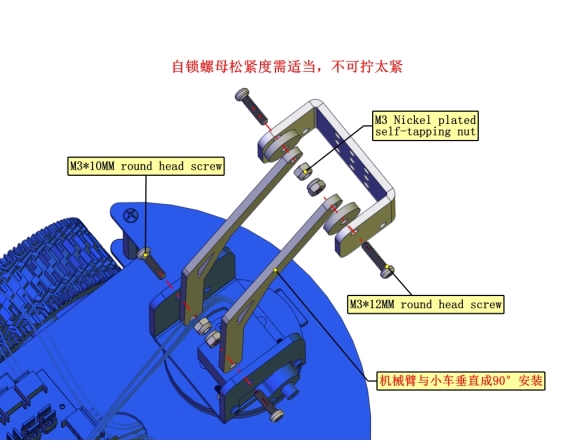

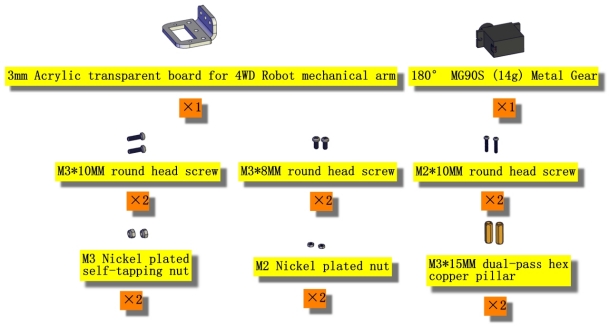

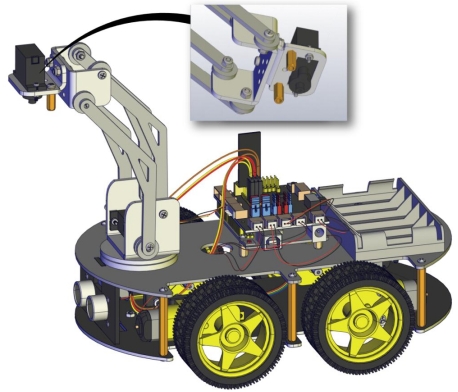

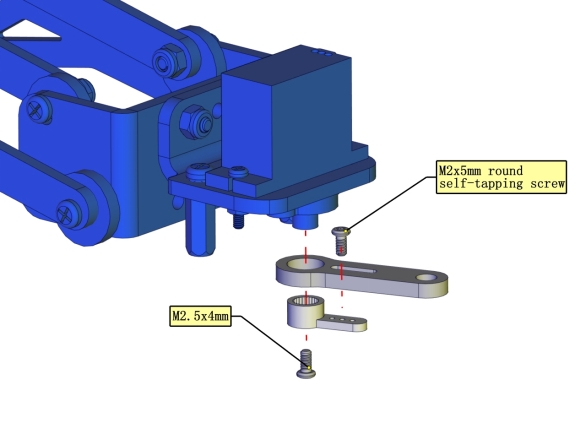

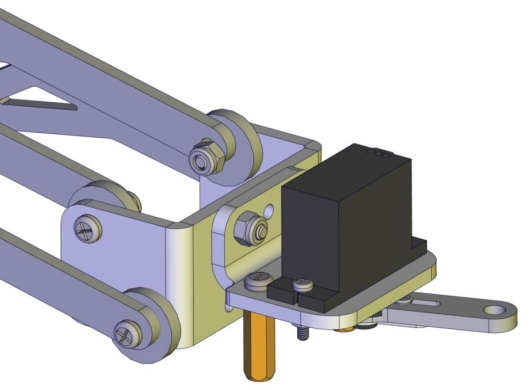

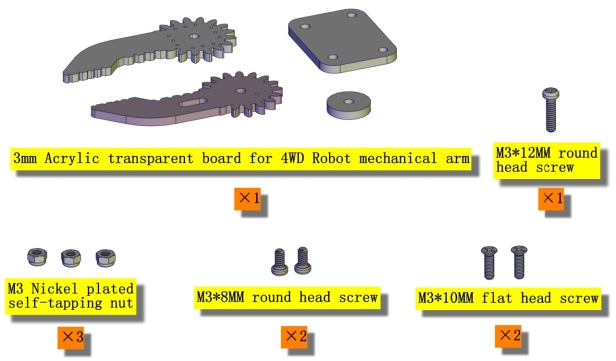

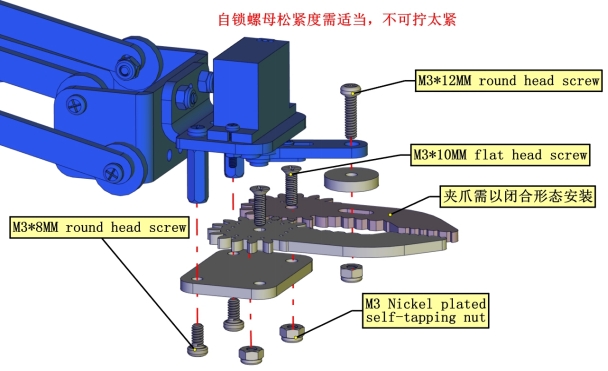

Install Robot Arm Smart Car

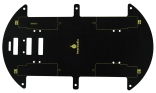

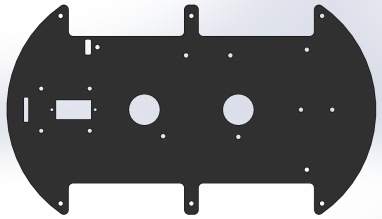

Note: Peel the plastic film off the board first when installing the smart car.

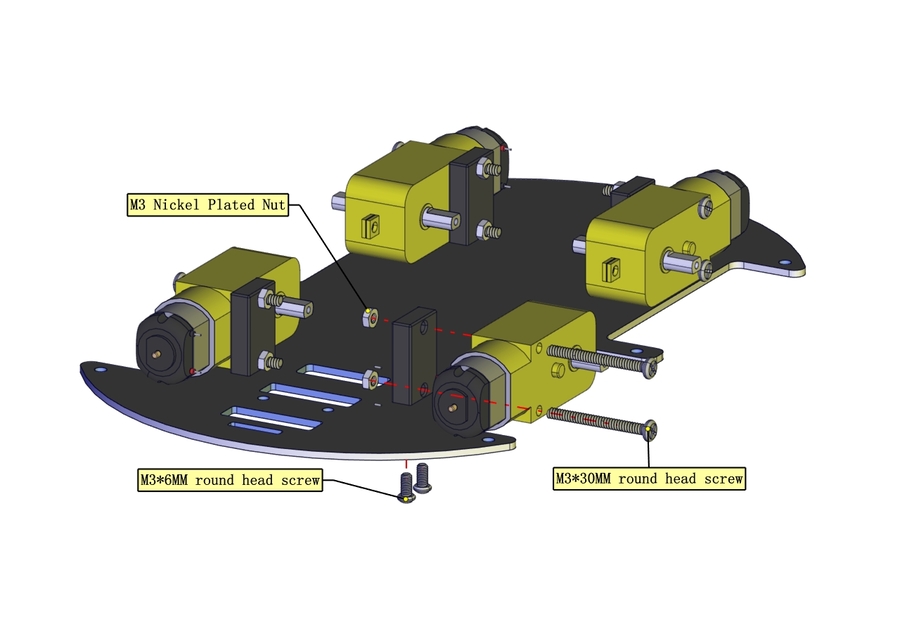

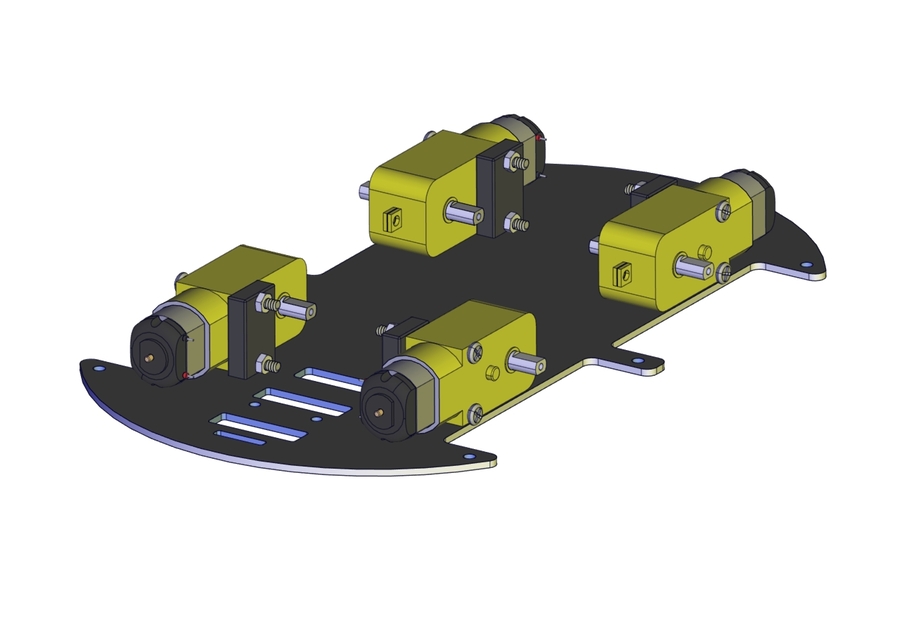

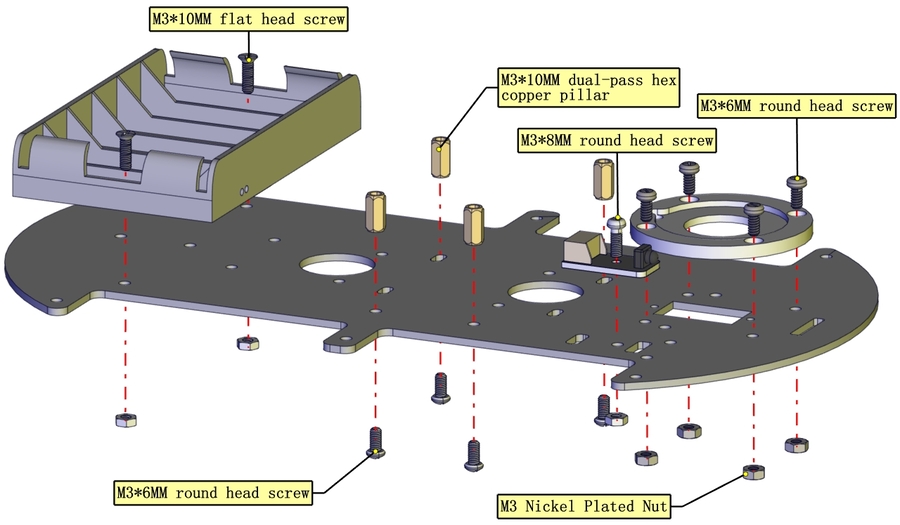

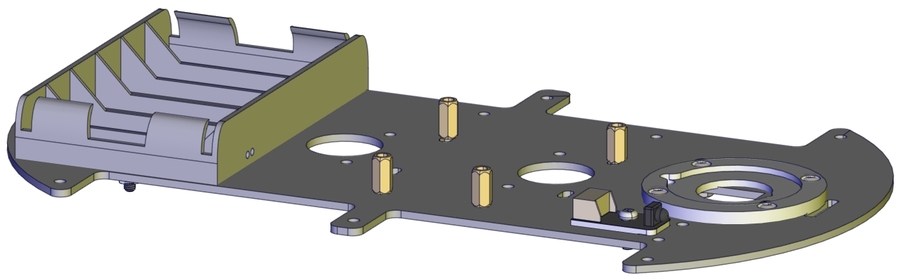

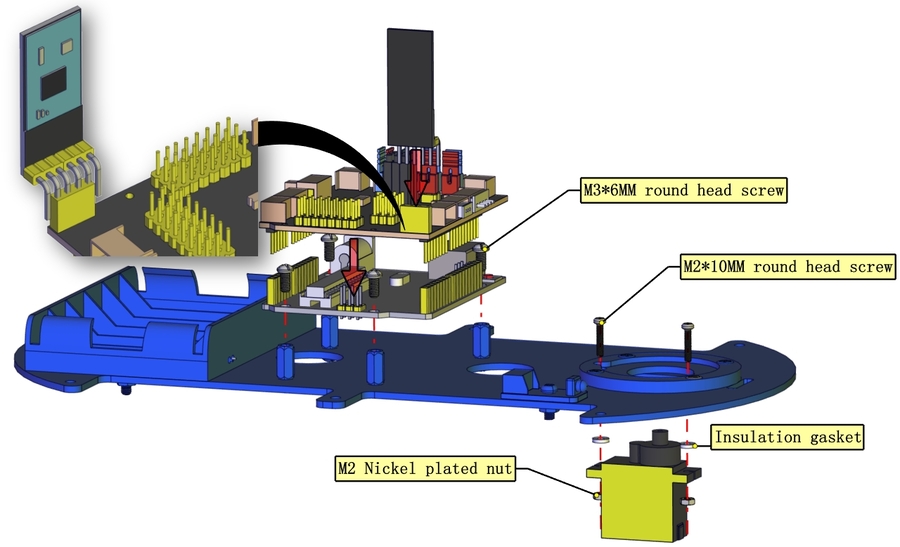

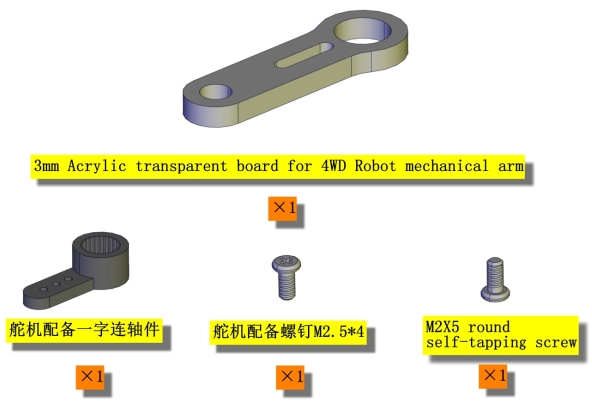

Assemble Body

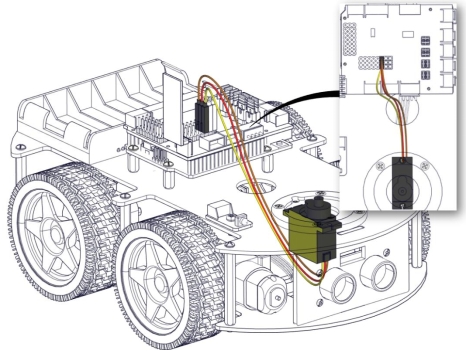

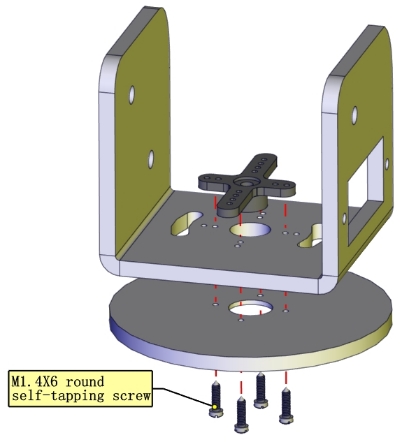

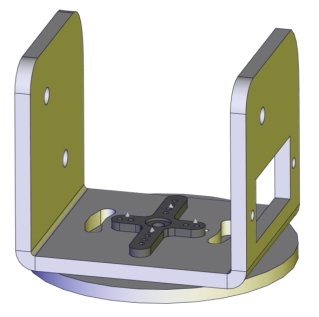

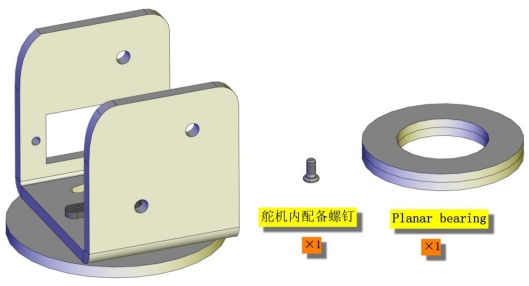

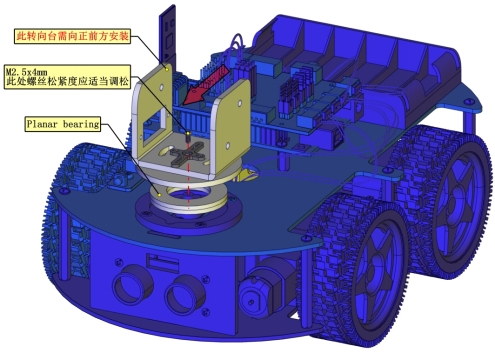

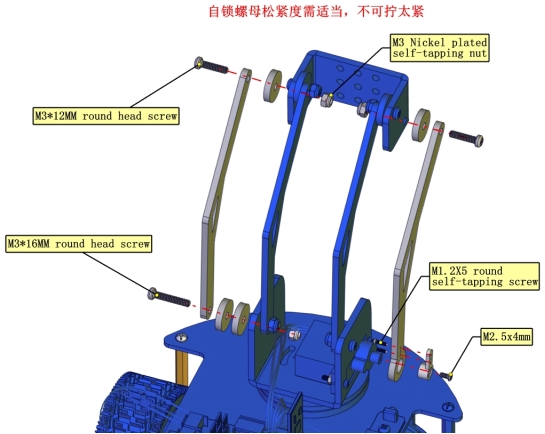

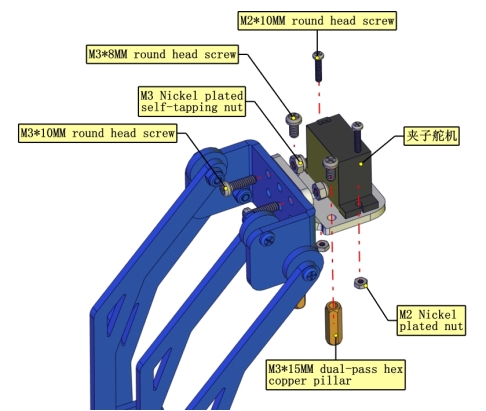

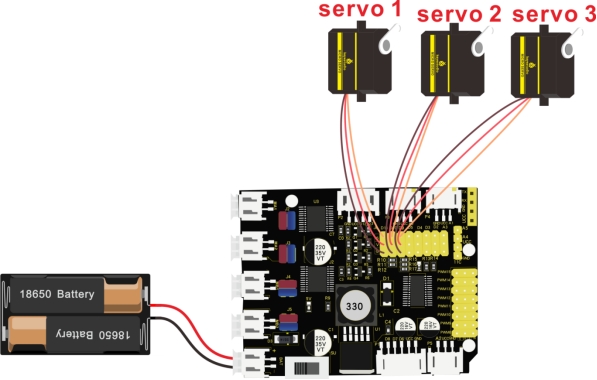

The following code is used to initialize the angle value of servo. Copy the code in the Arduino IDE and plug in power, then three servos will rotate to an initial angle.

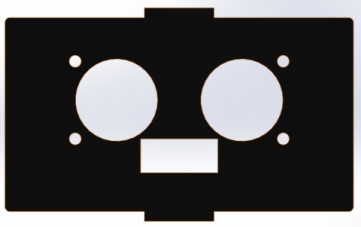

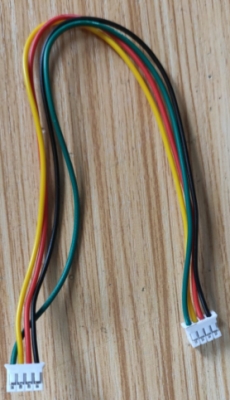

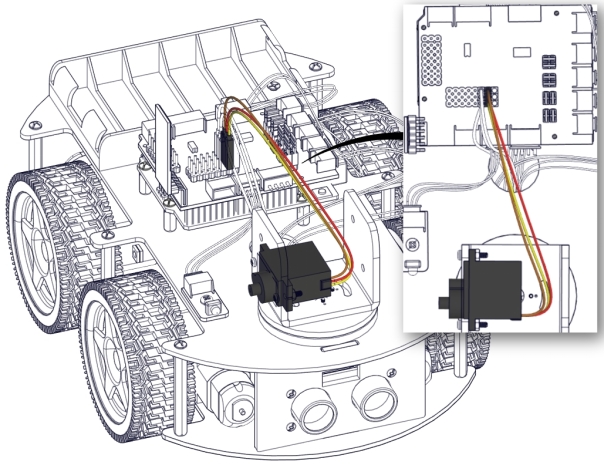

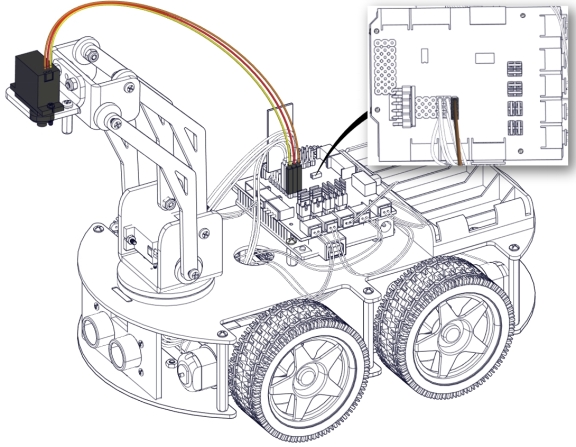

Wiring Diagram

Note: servo 3 sits on the base

Test Code

Installation

Projects

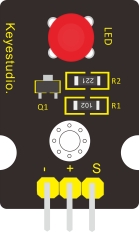

Project 1: LED Light

1. Description:

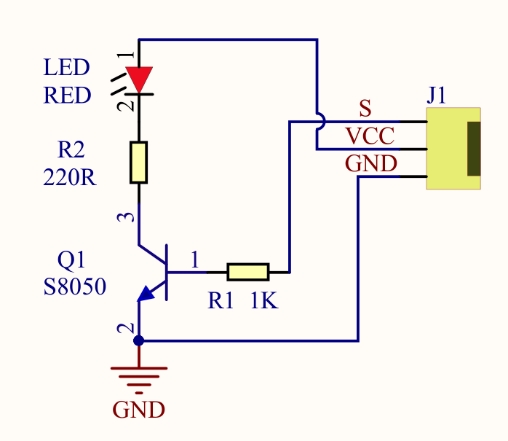

For starters and enthusiasts, LED Blink is a fundamental program. LED, the abbreviation of light emitting diodes, consists of Ga, As, P, N chemical compounds and so on. The LED can flash in diverse color by altering the delay time in the test code. When in control, power on GND and VCC, the LED will be on if S end is in high level; nevertheless, it will go off.

2. Specification:

Control interface: digital port

Working voltage: DC 3.3-5V

Pin spacing: 2.54mm

LED display color: red

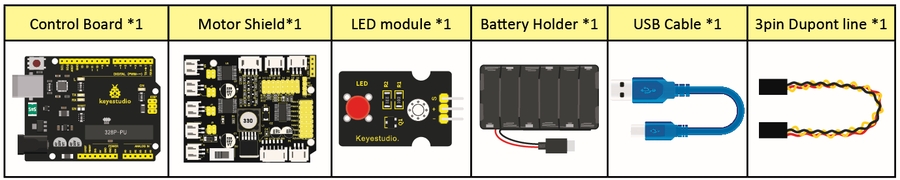

3. What You Need:

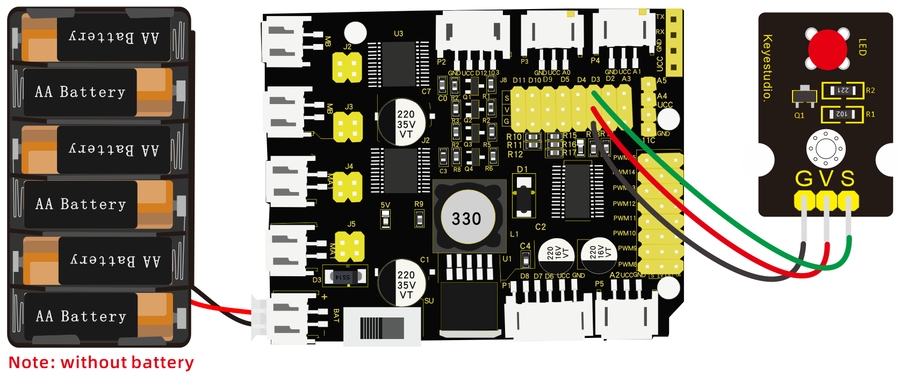

4. Wiring Diagram:

The pin -, + and S of LED module are connected to G, V and D3 of shield.

5. Test Code:

6. Test Result:

Upload the program, LED flashes with an interval of 1s.

7. Code Explanation:

pinMode(ledPin,OUTPUT) - This function denotes that the pin is INPUT or OUTPUT.

digitalWrite(ledPin,HIGH) - When pin is OUTPUT, we can set it to HIGH(output 5V) or LOW(output 0V)

8. Extension Practice:

We succeed in blinking the LED. Next, let’s observe what LED will change if we modify the delaying time.

The test result shows that the LED flashes faster. Therefore, we can draw a conclusion that pins and time delaying affect flash frequency.

Last updated

Was this helpful?